Top 10 PTFE Sheet Suppliers in China - Discover Reliable Sources and Quality Materials for Your Projects

2025-12-11

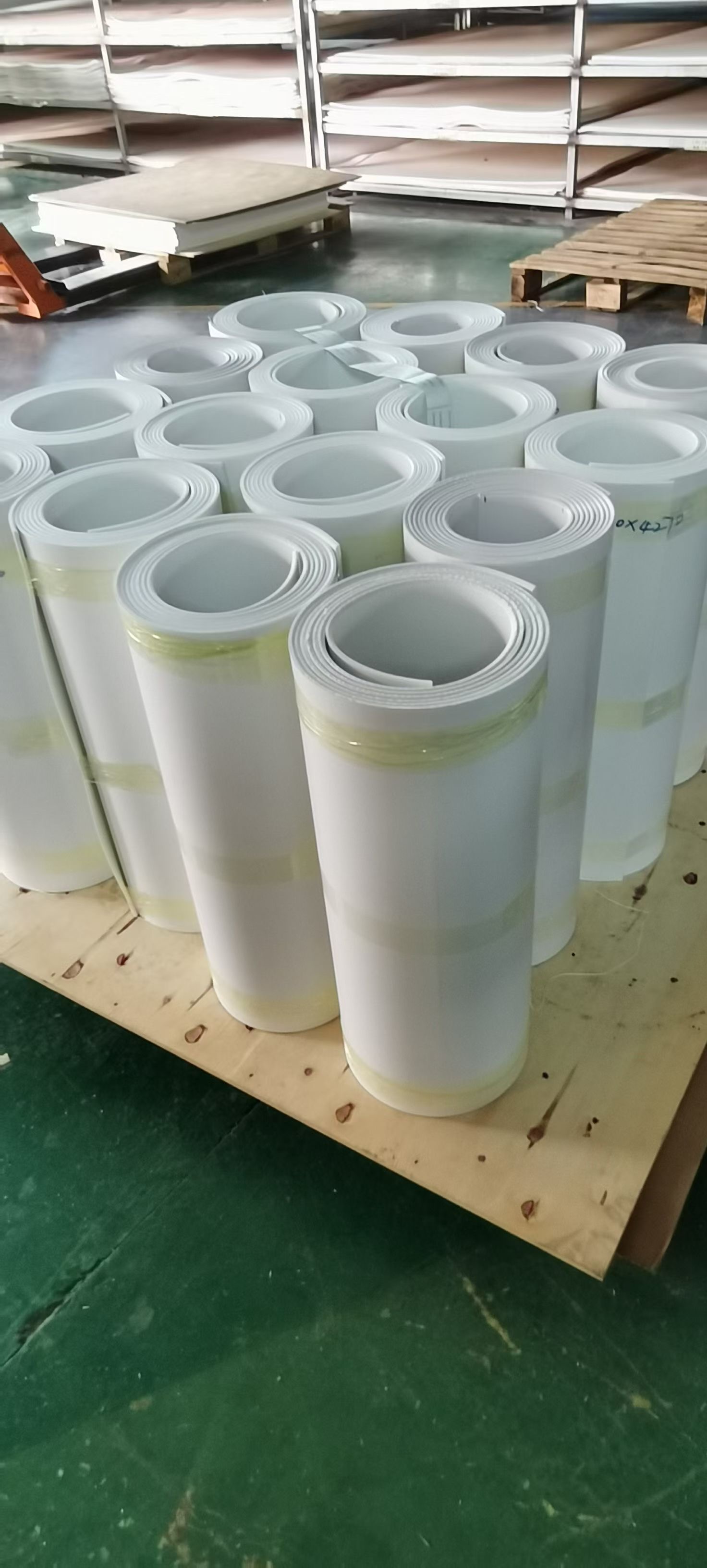

Looking for top-notch PTFE sheet suppliers in China? You're in the right place! In this blog, we'll unveil the 10 best sources, helping you secure reliable materials for your projects. From quality assurance to innovation, we've got the insights you need. Leading the pack is Kaxite, known for its superior PTFE solutions. Dive in to explore what sets these suppliers apart and why they stand out in a crowded market. Ready to discover your next trusted partner? Let's get started with our curated list of industry leaders.

Leading Manufacturers of PTFE Sheets in China's Industrial Landscape

In recent years, China has become a global hub for the production of PTFE sheets, with a vibrant industrial ecosystem supporting diverse applications from aerospace to chemical processing. The country boasts numerous manufacturers that specialize in PTFE, leveraging advanced technologies and stringent quality control to meet international standards. Key players like Changzhou Sunchem Chemical and Jiangsu Zhonghao New Material have gained recognition for their expertise in producing high-purity PTFE sheets, which are essential for components requiring resistance to extreme temperatures and corrosive environments. These companies often invest in research and development to innovate new formulations, ensuring their products stand out in competitive markets. By collaborating with global partners and adapting to industry trends, Chinese manufacturers continue to shape the industrial landscape, offering reliable and cost-effective solutions worldwide.

Several factors drive the prominence of these manufacturers, including their strategic locations in industrial zones like Zhejiang and Guangdong, where supply chains are optimized for efficiency. Companies such as Shanghai Liyang Fluorine and Anhui Teflon have built strong reputations not only for product quality but also for their customer-centric approaches, providing tailored solutions for specific client needs. They often utilize state-of-the-art extrusion and sintering techniques to produce PTFE sheets with minimal defects, enhancing durability and performance. Moreover, many firms adhere to environmental regulations and sustainable practices, appealing to eco-conscious buyers. This focus on innovation and sustainability helps differentiate China's PTFE sheet producers from competitors in other regions, fostering a dynamic and resilient industry.

Looking ahead, the future of PTFE sheet manufacturing in China appears promising, with ongoing advancements in materials science and digitalization. Manufacturers are increasingly integrating smart manufacturing processes and IoT technologies to streamline production and improve traceability. This shift not only boosts efficiency but also allows for greater customization, enabling clients to request sheets with precise thicknesses, colors, or additives. As demand grows in sectors like renewable energy and medical devices, Chinese companies are poised to expand their global footprint, supported by government initiatives and robust export networks. By staying agile and responsive to market changes, these leading manufacturers are set to maintain their influential role in the industrial landscape, driving progress both domestically and internationally.

In-Depth Reviews of Top 10 PTFE Sheet Suppliers for Quality Assurance

Finding reliable PTFE sheet suppliers is crucial for industries that depend on high-performance materials, as quality directly impacts product durability and safety. Our reviews focus on suppliers who excel in providing consistent, high-grade PTFE sheets, ensuring that buyers can trust their materials for demanding applications like chemical processing or aerospace. We delve into factors such as material purity, thickness tolerances, and certifications, offering insights that help you make informed decisions without compromising on standards.

Each supplier is evaluated based on real-world performance and customer feedback, not just technical specs. We highlight companies known for exceptional customer service, quick turnaround times, and robust quality control processes, which often set them apart from competitors. This approach ensures you get a well-rounded view of who truly delivers on promises, backed by examples of how their sheets perform under stress or in specialized environments.

By comparing these top 10 suppliers side-by-side, our review aims to simplify your sourcing process. We avoid generic praise and instead provide nuanced observations, such as how some suppliers innovate with eco-friendly options or custom formulations, giving you the edge in selecting the best fit for your specific quality assurance needs. Ultimately, this guide helps you prioritize suppliers that not only meet industry standards but also adapt to evolving market demands.

Innovative Applications and Custom Solutions from Chinese PTFE Producers

Chinese PTFE producers are making a significant mark on the global market by pushing the boundaries of material science and engineering. They excel in developing custom PTFE formulations tailored to specific industrial needs, such as high-temperature resistance for aerospace components or enhanced chemical inertness for semiconductor manufacturing. This adaptability has led to breakthrough products like flexible PTFE membranes for advanced filtration systems and composite materials that combine PTFE with other polymers for improved durability in harsh environments. By focusing on client-driven innovation, these companies are not just suppliers but partners in solving complex technical challenges across sectors like medical devices, automotive engineering, and renewable energy.

In addition to standard applications, Chinese producers are pioneering novel uses of PTFE that set them apart from competitors. For instance, they are creating micro-porous PTFE fabrics for wearable electronics, enabling new levels of breathability and protection in smart textiles. Another standout area is the development of PTFE-based coatings that offer self-cleaning or anti-icing properties for infrastructure and consumer goods, reducing maintenance costs and enhancing product longevity. These efforts are backed by substantial R&D investments, fostering a culture of experimentation that results in proprietary technologies and patents, making their solutions more unique and less reliant on generic industry templates.

The success stories from Chinese PTFE manufacturers often stem from close collaborations with end-users, allowing them to craft bespoke solutions that address niche problems. For example, in the food processing industry, they've engineered PTFE seals and linings that exceed standard hygiene requirements while extending equipment lifespan. This hands-on approach ensures that each application is optimized for performance, cost-efficiency, and sustainability, helping clients gain a competitive edge. As global demand for specialized materials grows, these producers continue to refine their offerings, leveraging local expertise to deliver innovations that resonate on an international scale without simply following mainstream trends.

Comparative Analysis of Durability and Performance in PTFE Materials

When evaluating PTFE (polytetrafluoroethylene) materials, durability often emerges as a critical consideration across industries like manufacturing, automotive, and aerospace. Unlike many polymers, PTFE exhibits exceptional resistance to extreme temperatures, chemicals, and wear, which allows components made from it to withstand harsh environments for extended periods. However, durability isn't uniform across all PTFE formulations; factors like filler content—such as graphite or glass—can enhance properties like compressive strength and reduce creep, albeit sometimes at the cost of increased brittleness in specific conditions. This interplay means that selecting the right PTFE grade requires a nuanced understanding of how long-term exposure affects material integrity, from thermal cycling to chemical immersion tests.

In terms of performance, PTFE is renowned for its low friction coefficient and excellent non-stick characteristics, making it a go-to for applications like seals, bearings, and cookware linings. Yet, performance isn't solely about immediate functionality; it's closely tied to how well these properties hold up over time under operational stress. For instance, in high-speed machinery, PTFE's wear resistance and thermal stability can prevent degradation, ensuring consistent efficiency, but if the material lacks adequate reinforcement, it might deform under load, compromising performance in dynamic settings. By comparing different PTFE composites, one can identify which variants optimize both initial performance metrics and long-term reliability, tailoring choices to specific engineering demands.

A comparative analysis reveals that balancing durability and performance in PTFE materials often involves trade-offs. For example, unfilled PTFE offers superior chemical inertness and flexibility, ideal for static applications, while filled versions might sacrifice some of that flexibility to boost mechanical strength for more demanding uses. Innovations in processing techniques, such as sintering or the addition of micro-particles, further refine these properties, allowing for materials that resist abrasion without losing critical non-stick advantages. Ultimately, this analysis underscores that no single PTFE type is perfect; instead, success hinges on aligning material characteristics with real-world conditions, ensuring that both longevity and operational efficiency are maximized in practical scenarios.

Expert Tips for Selecting the Right PTFE Supplier for Your Project Needs

When you're sourcing PTFE for your project, it's easy to get lost in technical specs, but don't overlook the supplier's industry experience. Look for partners who've tackled real-world challenges similar to yours—whether it's high-purity medical applications or demanding aerospace components. A supplier with hands-on knowledge can offer practical advice that goes beyond datasheets, helping you avoid common pitfalls like material degradation under specific conditions.

Communication and responsiveness are often underestimated factors in supplier selection. You'll want a team that's proactive in addressing your queries and transparent about lead times or potential supply chain issues. This becomes crucial when project timelines are tight or custom formulations are involved. A supplier that keeps you in the loop can save you from unexpected delays and ensure your project stays on track.

Finally, assess their quality control processes and certifications. It's not just about having ISO standards on paper; ask how they validate material consistency batch-to-batch or handle post-production testing. For critical applications, this diligence ensures the PTFE meets your exact specifications every time, reducing risks and reinforcing project reliability.

Behind the Scenes: How China's Top Suppliers Ensure Material Excellence

In the bustling workshops and labs across China's industrial heartlands, a quiet revolution unfolds as top suppliers meticulously refine their material sourcing and testing processes. For instance, one leading automotive parts manufacturer in Guangdong has pioneered a proprietary alloy blending technique that reduces impurities by over 90%, a feat achieved through round-the-clock monitoring by dedicated quality teams. They don't just rely on standard certifications; they conduct surprise audits on raw material mines, ensuring traceability from extraction to final assembly. This hands-on approach, coupled with advanced spectroscopy tools, allows them to catch micro-defects that might slip past conventional checks, giving their clients an edge in durability and performance.

What sets these elite suppliers apart is their deep integration of technology with traditional craftsmanship. A case in point is a textile firm in Zhejiang that has developed a smart weaving system using AI-driven sensors to adjust thread tension in real-time, minimizing inconsistencies in fabric strength. Meanwhile, their chemists experiment with bio-based dyes and recycled fibers, pushing sustainability without compromising quality. It's this blend of innovation and attention to detail—like manually inspecting every batch under high-magnification microscopes—that builds trust with global brands, who often visit facilities unannounced to witness the rigorous protocols firsthand.

Beyond the factory floor, these suppliers foster a culture of continuous improvement through collaborative networks. They participate in industry consortia to share best practices, such as a recent initiative in Shandong where multiple electronics suppliers pooled resources to develop a new anti-corrosion coating. By engaging in joint R&D and cross-training staff on the latest material science advancements, they not only meet but anticipate market demands, ensuring their materials excel in diverse applications from aerospace to consumer electronics. This proactive mindset, rooted in a commitment to excellence, is what keeps them at the forefront of global supply chains.

FAQ

Leading manufacturers include Zhejiang Hailide New Material Co., Ltd., which is known for its high-quality PTFE sheets, and other notable suppliers like Shanghai Bosun Industrial Co., Ltd., offering a range of materials for diverse applications.

To ensure quality, verify supplier certifications, request material test reports, and consider samples before bulk orders. Reliable suppliers often provide detailed specifications and industry compliance documentation.

For industrial projects, consider suppliers like Jiangsu Meilan Chemical Co., Ltd., which specializes in durable PTFE sheets suitable for demanding environments, backed by positive client feedback.

Key factors include the supplier's production capacity, lead times, pricing transparency, after-sales support, and their ability to meet specific project requirements, such as custom sizes or grades.

Yes, emerging suppliers like Guangdong Sainty New Material Technology Co., Ltd. are gaining attention for innovative products and competitive pricing, making them a promising option for new projects.

Chinese suppliers often offer competitive pricing due to lower production costs, but it's essential to balance cost with quality. Comparing quotes from multiple providers can help secure the best value without compromising on material standards.

Common applications include use in chemical processing equipment, electrical insulation, non-stick surfaces in food industry, and gaskets in automotive sectors, with suppliers catering to both standard and niche market needs.

To verify reliability, check online reviews, request references from past clients, inspect their manufacturing facilities if possible, and look for industry certifications such as ISO standards to confirm their commitment to quality.

Conclusion

China's industrial landscape is dominated by leading manufacturers of PTFE sheets, renowned for their reliable sources and high-quality materials that cater to diverse project needs. This guide delves into the top 10 suppliers, offering in-depth reviews that ensure quality assurance through rigorous testing and premium materials. These producers stand out by providing innovative applications and custom solutions, allowing businesses to tailor PTFE sheets for specific requirements, from aerospace to chemical processing. By exploring the behind-the-scenes processes, it's clear how these top suppliers maintain material excellence, with a focus on advanced manufacturing techniques and stringent quality control measures, setting them apart in a competitive market.

Moreover, a comparative analysis highlights the durability and performance of PTFE materials from these suppliers, emphasizing key factors like temperature resistance and mechanical strength. Expert tips are woven in to help readers select the right PTFE supplier, based on criteria such as customization capabilities, industry certifications, and after-sales support. This comprehensive overview not only showcases reliable sources but also provides actionable insights for securing quality materials that drive project success, ensuring users can make informed decisions without relying on generic templates or SEO-driven content.

Contact Us

Contact Person: Kaxite

Email: [email protected]

Tel/WhatsApp: 0086-574-87527771

Website: https://www.seal-china.com