3D printing is utilized in the rapid prototyping process

2023-10-16

3D printing, also known as additive manufacturing, is a popular technology used for creating rapid prototypes. It involves building three-dimensional objects layer by layer from a digital design file. Here's how 3D printing is utilized in the rapid prototyping process:

1. Design: The first step in 3D printing a rapid prototype is creating a digital design file using computer-aided design (CAD) software. The design can be created from scratch or based on existing 3D models.

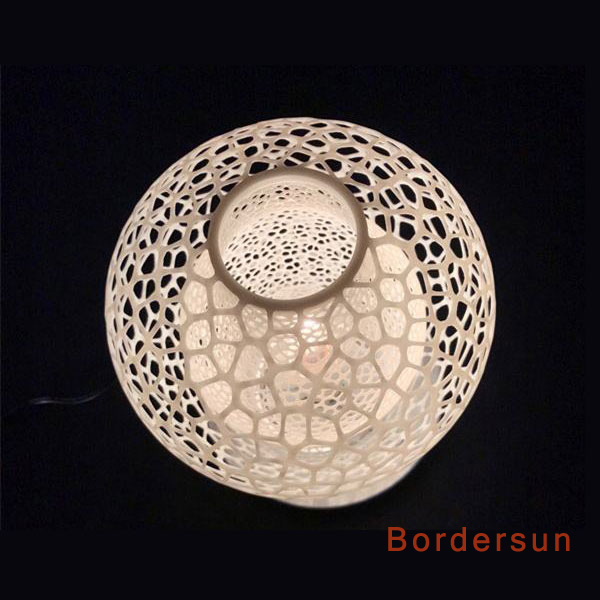

2. Material Selection: There is a wide range of 3D printing materials available, including plastics, metals, resins, ceramics, and composites. The choice of material depends on factors such as the desired properties of the prototype, functional requirements, visual appearance, and budget.

3. Printing Process: Once the design file is prepared, it is sent to a 3D printer. The 3D printer follows a layer-by-layer printing process to create the physical prototype. The specific printing process varies depending on the technology used, such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), or direct metal laser sintering (DMLS).

4. Post-Processing: After the 3D printing is complete, post-processing steps may be required to improve the prototype's appearance, surface finish, or mechanical properties. This may include removing support structures, sanding, polishing, painting, or applying other finishes as needed.

5. Evaluation and Testing: The 3D printed rapid prototype can then be evaluated and tested for its functionality, fit, form, and aesthetics. This allows for the identification of design flaws, potential improvements, and necessary iterations in the product development process.

6. Iterations and Refinement: One of the key advantages of 3D printing rapid prototypes is the ability to quickly iterate and refine designs. If modifications are needed, the digital design file can be adjusted, and a new prototype can be printed relatively easily and cost-effectively.

7. Cost and Time Efficiency: 3D printing rapid prototypes can be more cost-effective and time-efficient compared to traditional prototyping methods that involve custom tooling or molds. With 3D printing, there is no need for expensive tooling or lengthy setup processes, allowing for faster turnaround times and lower costs for producing each iteration.

3D printing rapid prototypes has revolutionized the product development process, enabling designers and engineers to quickly visualize and test their ideas before committing to full-scale production. It allows for faster design iterations, reduced lead times, and improved collaboration among team members. Additionally, 3D printing has expanded the possibilities for complex geometries and customized designs that were previously challenging to achieve using traditional manufacturing methods.